Embracing Equipment Maintenance Automation: A Path to Enhanced Efficiency and Accuracy

In today’s fast-paced manufacturing landscape, Equipment Maintenance Automation has emerged as a crucial strategy for businesses seeking to optimize their operations and maximize productivity. Traditional equipment maintenance processes, often manual and error-prone, can lead to costly downtime and reduced asset lifespan. RPA (Robotic Process Automation) powered by Python, AI, and cloud-based solutions offers a transformative approach to Equipment Maintenance Automation, enabling manufacturers to streamline their processes, enhance accuracy, and achieve significant operational benefits.

Python, AI, and Cloud: The Power Trio for Equipment Maintenance Automation

Python’s Role in Equipment Maintenance Automation

Python’s versatility and extensive library ecosystem make it an ideal choice for developing Equipment Maintenance Automation solutions. Python-based unattended bots can automate repetitive tasks such as:

- Scheduling preventive maintenance based on equipment usage data

- Monitoring equipment condition through sensor data analysis

- Generating and managing work orders

Attended Bots for Enhanced User Experience

Attended bots, also built with Python, provide a collaborative automation experience. They assist human operators with tasks such as:

- Identifying and diagnosing equipment issues

- Accessing maintenance history and documentation

- Creating and updating work orders

Python’s flexibility allows for extensive customization, ensuring that attended bots seamlessly integrate with existing workflows.

Cloud Platforms: Supercharging Automation

Cloud platforms offer a comprehensive suite of features and capabilities that far surpass traditional RPA/workflow tools. They provide:

- Scalability to handle large volumes of data and complex automation processes

- Reliability and security to ensure uninterrupted operations

- Integration with other cloud services for data analytics, machine learning, and more

AI for Enhanced Accuracy and Efficiency

AI techniques empower Equipment Maintenance Automation systems to:

- Improve accuracy through image recognition for equipment inspection

- Handle edge cases and exceptions using natural language processing (NLP)

- Leverage Generative AI for predictive maintenance and anomaly detection

By harnessing the combined power of Python, AI, and cloud platforms, manufacturers can unlock the full potential of Equipment Maintenance Automation, driving operational efficiency, maximizing asset lifespan, and gaining a competitive edge in the manufacturing industry.

Building the Equipment Maintenance Automation Solution

The Equipment Maintenance Automation process using Python and cloud involves the following steps:

- Data Collection and Analysis: Collect data from sensors, maintenance records, and other sources to create a comprehensive view of equipment health.

- Preventive Maintenance Scheduling: Use Python to analyze data and determine optimal maintenance schedules based on equipment usage and condition.

- Equipment Condition Monitoring: Monitor equipment condition in real-time using Python-based bots that analyze sensor data and identify potential issues.

- Work Order Management: Automate the creation, assignment, and tracking of work orders using Python bots integrated with cloud-based work order management systems.

Data Security and Compliance

Data security and compliance are paramount in manufacturing. Python and cloud platforms provide robust security features to protect sensitive data and ensure compliance with industry regulations.

Advantages of Python over No-Code RPA/Workflow Tools

Python offers several advantages over no-code RPA/workflow tools for Equipment Maintenance Automation:

- Flexibility and Customization: Python allows for extensive customization to meet specific automation needs and integrate with existing systems.

- Scalability and Performance: Python can handle large volumes of data and complex automation processes, ensuring scalability and performance.

- Open Source and Community Support: Python’s open-source nature and large community provide access to a wealth of resources and support.

Algorythum’s Approach

Algorythum takes a Python-based approach to Equipment Maintenance Automation due to client dissatisfaction with the performance and limitations of off-the-shelf automation platforms. Algorythum’s custom Python solutions provide:

- Tailored Automation: Solutions tailored to specific business needs and processes.

- Enhanced Performance: Automation that can handle complex processes and large data volumes efficiently.

- Seamless Integration: Integration with existing systems and data sources for a comprehensive automation solution.

By leveraging Python and our expertise in cloud-based solutions, Algorythum empowers manufacturers to build robust and scalable Equipment Maintenance Automation systems that drive operational efficiency and maximize asset lifespan.

The Future of Equipment Maintenance Automation

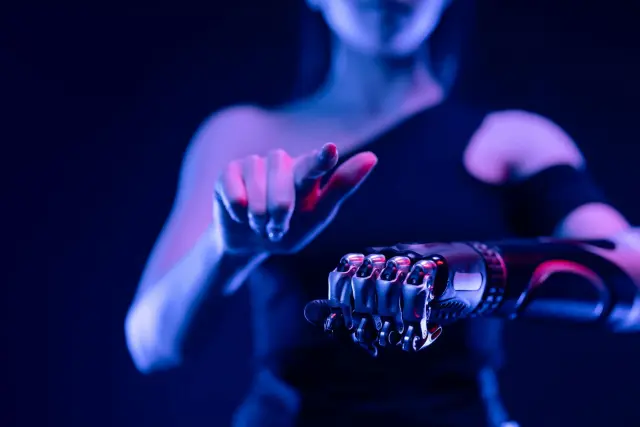

The future of Equipment Maintenance Automation holds exciting possibilities for further enhancing the proposed solution:

- Predictive Maintenance: Leveraging AI and machine learning to predict equipment failures and schedule maintenance proactively.

- Augmented Reality (AR): Empowering technicians with AR headsets to access real-time equipment data and instructions.

- Blockchain: Ensuring data integrity and transparency in maintenance records and work order management.

Subscribe and Contact Us

Subscribe to our blog to stay updated on the latest trends and advancements in Equipment Maintenance Automation and other industry-specific automation solutions.

Contact our team today for a free feasibility and cost estimate for your custom Equipment Maintenance Automation requirements. Algorythum’s experts will work with you to develop a tailored solution that meets your specific needs and drives operational efficiency.

Algorythum – Your Partner in Automations and Beyond

At Algorythum, we specialize in crafting custom RPA solutions with Python, specifically tailored to your industry. We break free from the limitations of off-the-shelf tools, offering:

- A team of Automation & DevSecOps Experts: Deeply experienced in building scalable and efficient automation solutions for various businesses in all industries.

- Reduced Automation Maintenance Costs: Our code is clear, maintainable, and minimizes future upkeep expenses (up to 90% reduction compared to platforms).

- Future-Proof Solutions: You own the code, ensuring flexibility and adaptability as your processes and regulations evolve.