Material Handling Automation: The Human Touch to Manufacturing Efficiency

In the fast-paced manufacturing industry, optimizing material handling processes is crucial for maintaining efficiency and accuracy. Material Handling Automation offers a solution by leveraging Python, AI, and cloud-based technologies to streamline material flow and minimize manual handling efforts. Embracing these advancements can revolutionize manufacturing processes, empowering businesses to achieve greater productivity and cost savings.

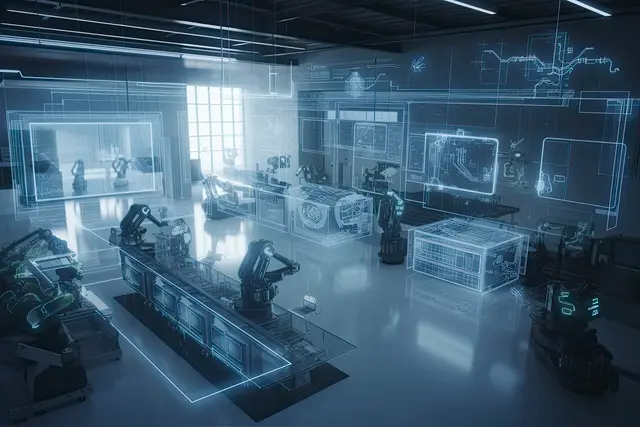

Python’s versatility and AI’s analytical capabilities, when combined with the scalability of cloud-based solutions, create a powerful ecosystem for Material Handling Automation. This integration allows for the seamless coordination of conveyor systems, robotic arms, and AGVs, transforming material transportation within manufacturing facilities. By automating repetitive tasks and optimizing material flow, businesses can significantly reduce the risk of human error, improve safety, and enhance overall operational efficiency.

Python, AI, and the Cloud: The Dynamic Trio for Material Handling Automation

Unattended Bots: Python’s Powerhouse for Automation

Python’s versatility shines in the development of unattended bots for Material Handling Automation. These bots can autonomously execute repetitive tasks, such as monitoring inventory levels, managing production schedules, and controlling material flow. By leveraging Python’s extensive libraries and frameworks, businesses can create sophisticated bots that seamlessly integrate with existing systems, ensuring smooth and efficient operations.

Attended Bots: Empowering Humans with Automation

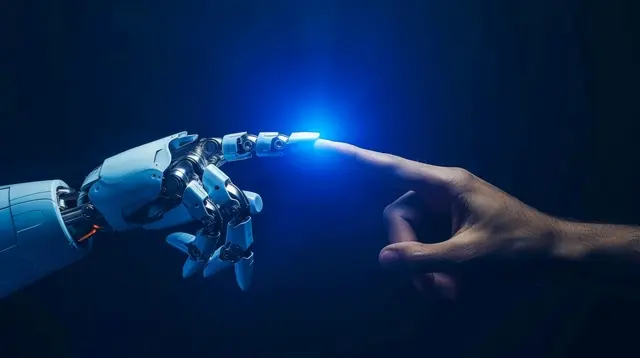

Attended bots extend the capabilities of Material Handling Automation by providing real-time assistance to human workers. Built with Python, these bots can automate specific tasks within a user’s workflow, such as data entry, order processing, and quality control. Attended bots not only enhance productivity but also reduce the cognitive load on workers, allowing them to focus on higher-value activities.

Cloud Platforms: The Orchestration Powerhouse

Cloud platforms offer a robust and scalable foundation for Material Handling Automation. They provide a comprehensive suite of tools and services that enable businesses to orchestrate complex automation workflows, manage data, and monitor system performance. Compared to traditional RPA/workflow tools, cloud platforms offer greater flexibility, scalability, and access to advanced technologies such as AI and machine learning.

AI: The Edge-Case Solver and Accuracy Booster

AI plays a pivotal role in enhancing the accuracy and efficiency of Material Handling Automation. Techniques like image recognition can enable bots to visually inspect materials, ensuring quality control. Natural language processing (NLP) empowers bots to understand and respond to human language, facilitating seamless communication between humans and machines. Generative AI can generate new data or automate complex tasks, further extending the capabilities of automation systems. By incorporating AI into their automation strategies, businesses can unlock new levels of efficiency and accuracy.

Building the Automation: A Step-by-Step Guide

1. Process Analysis

The first step in automating Material Handling Automation is to thoroughly analyze the processes involved. This includes identifying the tasks to be automated, the data required, and the expected outcomes. A clear understanding of the processes will ensure that the automation is tailored to the specific needs of the manufacturing facility.

2. Python Script Development

Using Python, developers can create scripts that automate the identified tasks. Python’s versatility and extensive libraries make it an ideal choice for developing robust and efficient automation solutions. These scripts can handle data manipulation, system integration, and decision-making, enabling the automation of complex processes.

3. Cloud Integration

Cloud platforms provide the infrastructure and services necessary to deploy and manage the automation scripts. By integrating with the cloud, businesses can benefit from scalability, reliability, and access to advanced technologies such as AI and machine learning. Cloud platforms also enable remote monitoring and control of the automation system, ensuring smooth operations.

4. Data Security and Compliance

Data security and compliance are paramount in manufacturing environments. Python scripts and cloud platforms must be configured to meet industry standards and regulations. Encryption, access controls, and regular security audits are essential to protect sensitive data and ensure compliance.

5. Python vs. No-Code RPA/Workflow Tools

While no-code RPA/workflow tools offer a quick and easy entry point to automation, they often lack the flexibility and customization capabilities of Python. Python’s open-source nature and vast ecosystem of libraries empower businesses to tailor their automation solutions to their specific requirements. Additionally, Python scripts can be easily integrated with existing systems and scaled to meet growing automation needs.

Algorythum’s Python-Based Approach

Algorythum’s focus on Python-based Material Handling Automation stems from our commitment to delivering tailored and scalable solutions that meet the unique challenges of the manufacturing industry. We recognize the limitations of off-the-shelf automation platforms and believe that Python’s versatility and power provide a superior foundation for building robust and effective automation systems.

The Future of Material Handling Automation

The future of Material Handling Automation is brimming with possibilities, driven by advancements in technology and the increasing adoption of AI and cloud computing. Here are some potential extensions to enhance the proposed solution:

- Predictive Maintenance: By leveraging AI and machine learning, automation systems can analyze data from sensors and equipment to predict maintenance needs, reducing downtime and optimizing resource utilization.

- Autonomous Material Handling: Advanced AI algorithms can enable robotic arms and AGVs to navigate and operate autonomously, further reducing the need for human intervention and enhancing safety.

- Real-Time Optimization: Cloud-based platforms can provide real-time data analytics and optimization capabilities, allowing businesses to adjust their Material Handling Automation strategies based on changing conditions and demand.

- Edge Computing: Edge computing devices can bring computation and storage closer to the manufacturing floor, enabling faster decision-making and reducing latency in automation systems.

To stay abreast of the latest advancements in Material Handling Automation and other industry-specific automation solutions, subscribe to our newsletter. Contact our team today for a free feasibility assessment and cost estimate tailored to your specific requirements. Together, we can unlock the full potential of automation and transform your manufacturing operations.

Algorythum – Your Partner in Automations and Beyond

At Algorythum, we specialize in crafting custom RPA solutions with Python, specifically tailored to your industry. We break free from the limitations of off-the-shelf tools, offering:

- A team of Automation & DevSecOps Experts: Deeply experienced in building scalable and efficient automation solutions for various businesses in all industries.

- Reduced Automation Maintenance Costs: Our code is clear, maintainable, and minimizes future upkeep expenses (up to 90% reduction compared to platforms).

- Future-Proof Solutions: You own the code, ensuring flexibility and adaptability as your processes and regulations evolve.