Quality Control Automation: Empowering Humans, Enhancing Manufacturing

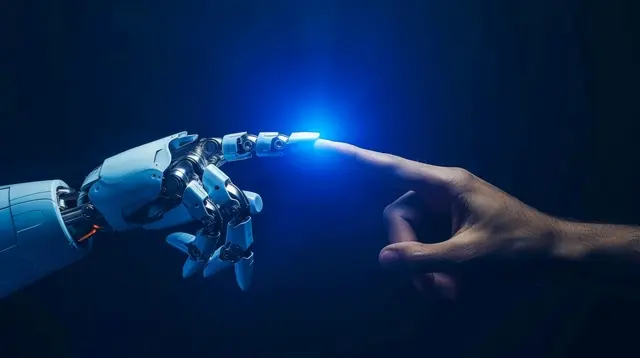

In the dynamic landscape of manufacturing, ensuring product quality is paramount. Quality Control Automation emerges as a game-changer, enabling businesses to streamline their inspection processes and drive operational excellence. Embracing Quality Control Automation with Python, AI, and cloud-based solutions empowers human inspectors, enhances accuracy, and unlocks new levels of efficiency.

By implementing RPA in conjunction with AI and cloud technologies, manufacturers can automate repetitive and error-prone tasks such as visual inspection, defect detection, and non-conformance management. This not only frees up inspectors to focus on more complex and value-added activities but also minimizes human error, leading to improved product quality and reduced rework.

Python, AI, and Cloud: Powerhouse Trio for Quality Control Automation

Python, AI, and the Cloud form a formidable alliance that empowers manufacturers to achieve unprecedented levels of automation and efficiency in their quality control processes.

Python: The Language of Unattended and Attended Bots

Python shines in developing both unattended and attended bots for Quality Control Automation. Unattended bots can autonomously execute repetitive tasks such as visual inspection and defect detection, freeing up human inspectors for more strategic work. Attended bots, on the other hand, collaborate with inspectors, providing real-time assistance and enhancing their decision-making capabilities. Python’s versatility and extensive library support make it an ideal choice for building customized bots tailored to specific inspection requirements.

Cloud Platforms: Orchestrating Automation at Scale

Cloud platforms offer a comprehensive suite of features and capabilities that far surpass traditional RPA/workflow tools. They provide a scalable and centralized environment for managing and orchestrating automation processes, enabling manufacturers to seamlessly integrate Quality Control Automation with other aspects of their operations. Additionally, cloud platforms offer access to advanced AI services that can significantly enhance the accuracy and effectiveness of automation.

AI: Enhancing Accuracy and Handling Edge Cases

AI plays a pivotal role in Quality Control Automation, particularly in image recognition, natural language processing (NLP), and generative AI (Gen AI). These techniques empower automation systems to:

- Identify defects with precision: AI-powered image recognition algorithms can analyze product images and detect defects that may be invisible to the naked eye.

- Classify non-conformances accurately: NLP enables automation systems to understand and categorize non-conformances based on predefined criteria, ensuring consistent and reliable reporting.

- Handle edge cases effectively: Gen AI can generate synthetic data to train automation systems on rare or complex scenarios, improving their ability to handle edge cases and make informed decisions.

By leveraging the combined power of Python, AI, and cloud platforms, manufacturers can transform their Quality Control Automation processes, unlocking new levels of efficiency, accuracy, and product quality.

Building the Quality Control Automation Solution

Process Analysis and Automation Design

The first step in building a Quality Control Automation solution is to thoroughly analyze the existing processes and identify the tasks that can be automated. This involves understanding the workflow, data flow, and decision-making involved in quality inspection, defect detection, and non-conformance management.

Once the automatable tasks are identified, the next step is to design the automation solution using Python and cloud technologies. This includes defining the data structures, algorithms, and integration points with other systems.

Step-by-Step Automation

The following steps outline how to automate the identified sub-processes using Python and cloud:

- Data Extraction: Use Python to extract data from various sources, such as inspection reports, images, and sensors.

- Image Analysis: Employ AI-powered image recognition algorithms to analyze product images and detect defects.

- Defect Classification: Train an NLP model to classify defects based on predefined criteria.

- Non-Conformance Reporting: Automatically generate non-conformance reports and route them to the appropriate personnel.

- Corrective Action Tracking: Track the status of corrective actions and provide updates to stakeholders.

Data Security and Compliance

Data security and compliance are paramount in manufacturing. Algorythum’s Quality Control Automation solution ensures that all data is handled securely and complies with industry regulations. The solution leverages cloud-based security measures such as encryption, access control, and audit trails.

Python vs. No-Code RPA/Workflow Tools

While no-code RPA/workflow tools offer a low-code/no-code approach to automation, they often lack the flexibility and customization capabilities of Python. Algorythum’s Quality Control Automation solution, built using Python, provides:

- Greater flexibility: Python allows for the development of highly customized automation scripts that can adapt to specific business requirements.

- Improved performance: Python is a high-performance language that can handle complex data processing and AI algorithms efficiently.

- Enhanced scalability: Python-based automation solutions can be easily scaled to meet growing automation needs.

Algorythum’s Differentiated Approach

Algorythum takes a different approach to Quality Control Automation because we recognize the limitations of off-the-shelf automation platforms. Our solution, built using Python and cloud technologies, offers:

- Tailor-made solutions: We work closely with our clients to understand their specific needs and develop customized automation solutions that meet their unique requirements.

- End-to-end expertise: Our team of experts possesses deep knowledge in Python, AI, and cloud technologies, ensuring seamless implementation and ongoing support.

- Proven track record: We have a proven track record of delivering successful Quality Control Automation solutions that have transformed manufacturing operations and improved product quality.

The Future of Quality Control Automation

The future of Quality Control Automation is bright, with emerging technologies offering exciting possibilities to further enhance its capabilities.

One promising area is the integration of Quality Control Automation with IoT (Internet of Things) devices. By connecting sensors and other devices to the automation system, manufacturers can gain real-time insights into product quality and performance. This data can be used to identify potential defects early on, predict maintenance needs, and optimize the manufacturing process.

Another area of innovation is the use of blockchain technology to ensure the integrity and traceability of quality control data. Blockchain can create a secure and immutable record of all inspection and non-conformance events, providing manufacturers with a trusted source of truth for quality assurance purposes.

We encourage readers to subscribe to our newsletter to stay updated on the latest advancements in Quality Control Automation and other industry-specific automation solutions. Contact our team today for a free feasibility and cost estimate for your custom Quality Control Automation requirements. Together, we can harness the power of technology to transform your manufacturing operations and achieve new levels of quality excellence.

Algorythum – Your Partner in Automations and Beyond

At Algorythum, we specialize in crafting custom RPA solutions with Python, specifically tailored to your industry. We break free from the limitations of off-the-shelf tools, offering:

- A team of Automation & DevSecOps Experts: Deeply experienced in building scalable and efficient automation solutions for various businesses in all industries.

- Reduced Automation Maintenance Costs: Our code is clear, maintainable, and minimizes future upkeep expenses (up to 90% reduction compared to platforms).

- Future-Proof Solutions: You own the code, ensuring flexibility and adaptability as your processes and regulations evolve.