Production Scheduling Automation: The Key to Unlocking Manufacturing Efficiency

In the fast-paced and competitive manufacturing industry, production scheduling is a critical process that can make or break a company’s success. However, traditional scheduling methods are often manual and time-consuming, leading to inefficiencies, errors, and missed deadlines.

Enter Production Scheduling Automation. This revolutionary approach leverages the power of Python, AI, and cloud-based solutions to automate the entire scheduling process, from order demand forecasting to resource allocation and real-time schedule adjustments. By automating these tasks, manufacturers can:

- Increase efficiency: Automate repetitive and time-consuming tasks to free up valuable human resources for more strategic initiatives.

- Improve accuracy: Eliminate manual errors and ensure schedules are based on real-time data, leading to more precise planning.

- Enhance flexibility: Adjust schedules in real-time to accommodate unexpected events or changes in demand, ensuring optimal production flow.

- Maximize resource utilization: Optimize resource allocation to avoid bottlenecks and underutilization, maximizing production capacity.

Unlock the Potential of Your Manufacturing Operations

Production scheduling automation is not just a buzzword; it’s a proven solution that can transform your manufacturing operations. By embracing this technology, you can unlock the following benefits:

- Increased productivity: Automated scheduling reduces production time and improves overall efficiency, leading to higher output.

- Reduced costs: By eliminating manual processes and optimizing resource utilization, manufacturers can significantly reduce operating expenses.

- Improved customer satisfaction: Accurate and timely scheduling ensures that orders are fulfilled on time and to specifications, enhancing customer satisfaction and loyalty.

- Competitive advantage: Automation gives manufacturers a competitive edge by enabling them to adapt quickly to changing market demands and stay ahead of the competition.

Conclusion

In today’s dynamic manufacturing landscape, production scheduling automation is no longer a luxury but a necessity. By leveraging the power of Python, AI, and cloud-based solutions, manufacturers can automate this critical process, unlock efficiency, improve accuracy, and gain a competitive advantage. Embrace the future of manufacturing and reap the rewards of intelligent production scheduling automation.

Python, AI, and Cloud: The Power Trio for Production Scheduling Automation

Python, AI, and cloud-based platforms play pivotal roles in revolutionizing production scheduling automation. Here’s how each technology contributes to this transformative process:

Python: The Language of Automation

Python is an ideal language for developing both unattended and attended bots for production scheduling automation.

- Unattended Bots: Python scripts can be used to automate repetitive and time-consuming tasks, such as data extraction, order processing, and schedule generation. These bots can run autonomously, 24/7, without human intervention.

- Attended Bots: Python can also be used to create attended bots that assist human operators in scheduling tasks. These bots can provide real-time data, automate data entry, and offer decision support, enhancing the efficiency and accuracy of manual scheduling processes.

Cloud Platforms: Powerful Orchestrators

Cloud platforms offer a comprehensive suite of features and capabilities that far surpass traditional RPA/workflow tools orchestrators. These platforms provide:

- Scalability: Cloud platforms can scale seamlessly to handle large volumes of data and complex scheduling scenarios.

- Flexibility: Cloud platforms offer a wide range of services and APIs that allow for customization and integration with existing systems.

- Security: Cloud platforms provide robust security measures to ensure the confidentiality and integrity of sensitive scheduling data.

AI: Enhancing Accuracy and Handling Edge Cases

AI techniques, such as image recognition, natural language processing (NLP), and generative AI (Gen AI), can significantly enhance the accuracy and capabilities of production scheduling automation systems.

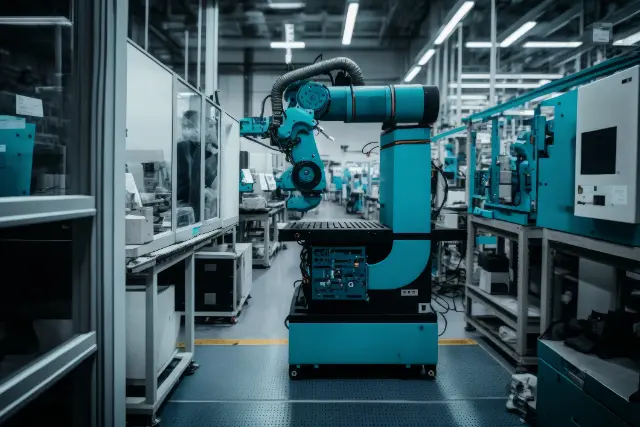

- Image Recognition: AI algorithms can analyze images of production lines to identify bottlenecks, equipment failures, and other anomalies, enabling proactive scheduling adjustments.

- NLP: NLP models can extract insights from unstructured data, such as customer orders and production reports, to improve demand forecasting and resource allocation.

- Gen AI: Gen AI techniques can generate optimal scheduling plans based on complex constraints and real-time data, handling even the most challenging edge cases.

Conclusion

The combination of Python, AI, and cloud-based platforms empowers manufacturers with a powerful toolkit for production scheduling automation. By leveraging these technologies, manufacturers can unlock new levels of efficiency, accuracy, and flexibility, gaining a competitive advantage in the dynamic manufacturing landscape.

Building the Production Scheduling Automation with Python and Cloud

Automating production scheduling involves several key sub-processes:

- Data Collection and Integration: Collect data from various sources, such as order management systems, resource availability databases, and production monitoring systems. Use Python scripts to extract, transform, and load (ETL) data into a centralized repository.

- Demand Forecasting: Utilize AI techniques, such as time series analysis and regression models, to forecast future demand based on historical data and market trends.

- Resource Allocation: Develop Python algorithms to allocate resources, such as machines, labor, and materials, to production orders based on availability, capacity, and skills.

- Schedule Generation: Use cloud-based optimization tools to generate production schedules that minimize production time, costs, and resource conflicts.

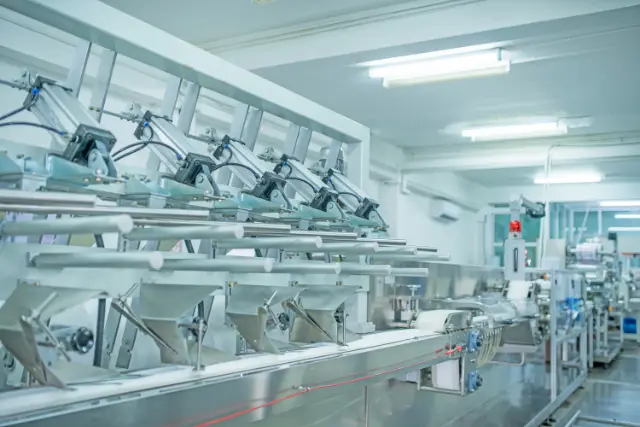

- Production Monitoring and Adjustment: Implement Python scripts and cloud-based dashboards to monitor production progress in real-time. Use AI algorithms to identify deviations from the schedule and trigger automatic adjustments.

Data Security and Compliance

Data security and compliance are paramount in manufacturing. Python and cloud platforms provide robust security measures, such as encryption, access controls, and audit trails, to ensure the confidentiality and integrity of sensitive scheduling data.

Python vs. No-Code RPA/Workflow Tools

While no-code RPA/workflow tools offer a low-code/no-code approach, they have limitations compared to Python:

- Customization: Python allows for greater customization and flexibility to handle complex scheduling scenarios and integrate with diverse systems.

- Scalability: Python scripts can be easily scaled to handle large volumes of data and complex scheduling requirements.

- Cost-Effectiveness: Building automations with Python is often more cost-effective than using proprietary no-code RPA/workflow tools.

Algorythum’s Approach

Algorythum takes a different approach by leveraging Python and cloud-based platforms because we understand the dissatisfaction clients face with off-the-shelf automation platforms. Our Python-based solutions offer:

- Tailor-made Solutions: Custom-built automations that cater to specific manufacturing needs and processes.

- Seamless Integration: Easy integration with existing systems and data sources, ensuring a smooth transition to automated scheduling.

- Continuous Improvement: Python’s open-source nature allows for ongoing enhancements and updates to keep pace with evolving manufacturing requirements.

Conclusion

Building production scheduling automation with Python and cloud provides manufacturers with a powerful and flexible solution that addresses the challenges of traditional scheduling methods. By leveraging Python’s customization capabilities, cloud platforms’ scalability, and AI’s analytical power, manufacturers can unlock new levels of efficiency, accuracy, and compliance in their production operations.

The Future of Production Scheduling Automation

The convergence of Python, AI, and cloud-based platforms has opened up a world of possibilities for enhancing production scheduling automation. Future technologies will further extend the capabilities of these solutions:

Edge Computing: Edge devices can collect and analyze real-time data from production lines, enabling more accurate and responsive scheduling adjustments.

5G and IoT: 5G networks and IoT devices will facilitate seamless communication and data exchange between machines, enabling automated scheduling based on real-time production conditions.

Digital Twins: Digital twins can create virtual replicas of production lines, allowing manufacturers to test and optimize scheduling scenarios before implementation.

Subscribe and Connect

To stay abreast of the latest advancements in production scheduling automation and other industry-specific automation solutions, subscribe to our newsletter.

For a free feasibility assessment and cost estimate tailored to your specific requirements, contact our team today. We are here to help you unlock the transformative power of automated production scheduling.

Algorythum – Your Partner in Automations and Beyond

At Algorythum, we specialize in crafting custom RPA solutions with Python, specifically tailored to your industry. We break free from the limitations of off-the-shelf tools, offering:

- A team of Automation & DevSecOps Experts: Deeply experienced in building scalable and efficient automation solutions for various businesses in all industries.

- Reduced Automation Maintenance Costs: Our code is clear, maintainable, and minimizes future upkeep expenses (up to 90% reduction compared to platforms).

- Future-Proof Solutions: You own the code, ensuring flexibility and adaptability as your processes and regulations evolve.