Embracing Tooling Management Automation for a Smarter Manufacturing Era

In the fast-paced manufacturing industry, every second counts. Streamlining operations is key to staying competitive, and tooling management automation is a game-changer in this regard.

Manual tool management processes are prone to errors, inefficiencies, and lost productivity. Tooling Management Automation addresses these challenges head-on, using advanced technologies like Python, AI, and cloud-based solutions to automate inventory tracking, maintenance scheduling, and tool life monitoring.

Tooling Management Automation brings numerous benefits to manufacturers, including:

- Reduced costs: Automated tool tracking eliminates the need for manual inventory checks, saving time and labor costs.

- Improved accuracy: Automated systems provide real-time visibility into tool availability, reducing errors and ensuring the right tools are always on hand.

- Increased productivity: By automating maintenance scheduling, manufacturers can minimize downtime and maximize tool utilization.

- Enhanced tool life: Automated tool life monitoring helps identify tools that need attention before they fail, preventing costly breakdowns.

Tooling Management Automation is a strategic investment for manufacturers looking to optimize their operations, reduce costs, and gain a competitive edge. By embracing this technology, manufacturers can unlock the potential for a smarter, more efficient, and more profitable future.

Python, AI, and the Cloud: Supercharging Tooling Management Automation

Python, AI, and cloud computing are the cornerstone technologies powering the next generation of tooling management automation solutions.

Python is a versatile programming language that is ideally suited for developing both unattended and attended bots for tooling management automation. Unattended bots can be programmed to perform repetitive tasks, such as inventory tracking and maintenance scheduling, without human intervention. Attended bots, on the other hand, can assist human workers with tasks that require more complex decision-making, such as tool selection and troubleshooting.

AI can be used to improve the accuracy and efficiency of tooling management automation systems. For example, AI-powered image recognition can be used to automatically identify tools from images, while natural language processing (NLP) can be used to extract data from maintenance logs and other unstructured documents.

Cloud platforms offer a number of advantages over traditional RPA/workflow tools orchestrators. Cloud platforms are more scalable, reliable, and secure, and they offer a wider range of features and functionality. Additionally, cloud platforms are constantly being updated with new features and capabilities, so tooling management automation systems built on cloud platforms can benefit from the latest advancements in automation technology.

Here are some specific examples of how AI can be used to enhance tooling management automation:

- Image recognition can be used to automatically identify tools from images, eliminating the need for manual data entry.

- Natural language processing (NLP) can be used to extract data from maintenance logs and other unstructured documents, providing a more complete view of tool usage and performance.

- Generative AI can be used to generate realistic data for testing and training tooling management automation systems.

By leveraging the power of Python, AI, and the cloud, manufacturers can build tooling management automation systems that are more accurate, efficient, and scalable than ever before.

Benefits of using cloud platforms for tooling management automation:

- Scalability: Cloud platforms can be easily scaled up or down to meet the changing needs of your business.

- Reliability: Cloud platforms are highly reliable and offer a 99.9% uptime guarantee.

- Security: Cloud platforms are secure and compliant with industry-leading security standards.

- Features and functionality: Cloud platforms offer a wide range of features and functionality, including built-in AI and machine learning capabilities.

- Cost-effectiveness: Cloud platforms are cost-effective and can be used to reduce the cost of tooling management automation.

Building the Tooling Management Automation Solution

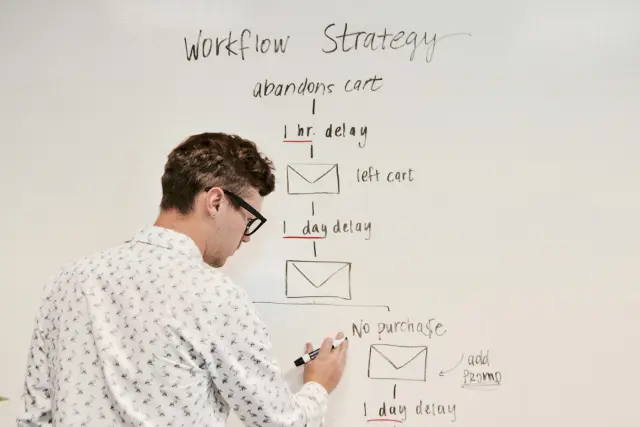

The first step in building a tooling management automation solution is to analyze the processes involved and identify the tasks that can be automated. Once the target tasks have been identified, the next step is to develop a Python script that can perform the automation.

The following are the key steps involved in automating tooling management processes using Python and the cloud:

- Data collection: The first step is to collect data from the various sources involved in tooling management, such as inventory systems, maintenance logs, and tool usage data. This data can be collected using a variety of methods, such as APIs, web scraping, and manual data entry.

- Data processing: Once the data has been collected, it needs to be processed and cleaned in order to make it usable for automation. This may involve tasks such as data validation, data transformation, and data normalization.

- Automation development: The next step is to develop the Python script that will perform the automation. The script should be designed to be efficient, reliable, and scalable.

- Deployment: Once the script has been developed, it needs to be deployed to the cloud. This may involve creating a virtual machine or container instance, and configuring the script to run on a schedule or on demand.

- Monitoring: Once the script has been deployed, it is important to monitor its performance and make sure that it is running as expected. This may involve setting up alerts and notifications, and regularly reviewing the script’s logs.

Data security and compliance are important considerations for any tooling management automation solution. It is important to make sure that the data collected and processed by the solution is secure and compliant with all applicable laws and regulations. This may involve implementing encryption, access controls, and other security measures.

Advantages of using Python for tooling management automation:

- Flexibility: Python is a versatile language that can be used to automate a wide range of tasks.

- Scalability: Python scripts can be easily scaled up or down to meet the changing needs of your business.

- Cost-effectiveness: Python is a free and open-source language, which can help to reduce the cost of tooling management automation.

Limitations of using no-code RPA/workflow tools for tooling management automation:

- Limited functionality: No-code RPA/workflow tools typically offer a limited range of functionality, which may not be sufficient for complex tooling management tasks.

- Lack of flexibility: No-code RPA/workflow tools are often not as flexible as Python scripts, which can make it difficult to customize the automation to meet your specific needs.

- Vendor lock-in: No-code RPA/workflow tools often require you to use their proprietary software, which can make it difficult to switch to another vendor if you are not satisfied with their service.

Why Algorythum takes a different approach to tooling management automation:

Algorythum takes a different approach to tooling management automation because we believe that Python is the best language for developing tooling management automation solutions. Python is flexible, scalable, and cost-effective, and it allows us to develop custom solutions that meet the specific needs of our clients.

We have witnessed client dissatisfaction with the performance of off-the-shelf automation platforms, and we believe that Python is a better approach for tooling management automation because it gives us the flexibility to develop solutions that are tailored to the specific needs of our clients.

The Future of Tooling Management Automation

The future of tooling management automation is bright. As technology continues to develop, we can expect to see even more powerful and sophisticated automation solutions emerge.

One area of future development is the use of artificial intelligence (AI) to further automate tooling management tasks. AI can be used to identify patterns and trends in data, and to make predictions about future events. This information can be used to improve the efficiency and effectiveness of tooling management automation solutions.

Another area of future development is the use of the Internet of Things (IoT) to connect tooling management systems to other devices and sensors. This will allow for real-time monitoring of tools and equipment, and will enable tooling management automation solutions to respond to changes in the environment in real time.

We encourage you to subscribe to our newsletter to stay up-to-date on the latest developments in tooling management automation. And if you are interested in learning more about how tooling management automation can benefit your business, please contact our team to get a free feasibility and cost-estimate for your custom requirements.

Algorythum is a leading provider of tooling management automation solutions. We have a team of experienced engineers who can help you develop a custom solution that meets the specific needs of your business.

Contact us today to learn more!

Algorythum – Your Partner in Automations and Beyond

At Algorythum, we specialize in crafting custom RPA solutions with Python, specifically tailored to your industry. We break free from the limitations of off-the-shelf tools, offering:

- A team of Automation & DevSecOps Experts: Deeply experienced in building scalable and efficient automation solutions for various businesses in all industries.

- Reduced Automation Maintenance Costs: Our code is clear, maintainable, and minimizes future upkeep expenses (up to 90% reduction compared to platforms).

- Future-Proof Solutions: You own the code, ensuring flexibility and adaptability as your processes and regulations evolve.